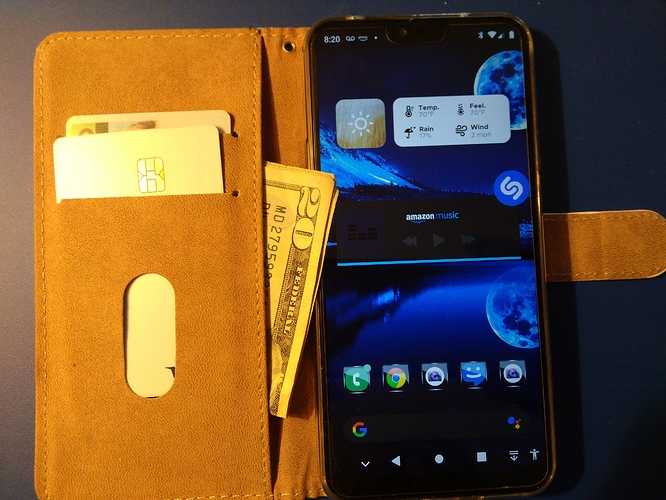

A little before Halloween, I looked online for how to make a DIY phone case. Why? Beacause there really are recent phones that no “protective phone case with built-in screen protector” case is made for them. Alcatel Idol 5s 6060s, if the bargain price phone i had found had been an Alcatel 6060x, I never would have tried to make my own phone case

The instructions for both DIY phone case methods say wrap your phone tightly in parchment paper (parchment paper is used for cooking and found next to wax paper, plastic wrap and aluminum foil) and hold it together with tape. And, leave plenty of room for each button and hole. They did not say tape does not stick well to the parchment paper.e

I tried mixing silicone caulk with corn starch to the consistency of flour dough. It did not cure. After a few days it was still soft and sticky.

I tried hot glue. The end result was amazing and effective.

I went to Walmart and bought a glue gun and a pack of Glow-In-The-Dark hot glue, Halloween time, remember?. The hot glue dried and cooled quickly. Within 10 minutes, the glue was room temperature. And the glue stuck to EVERYTHING except the parchment paper.

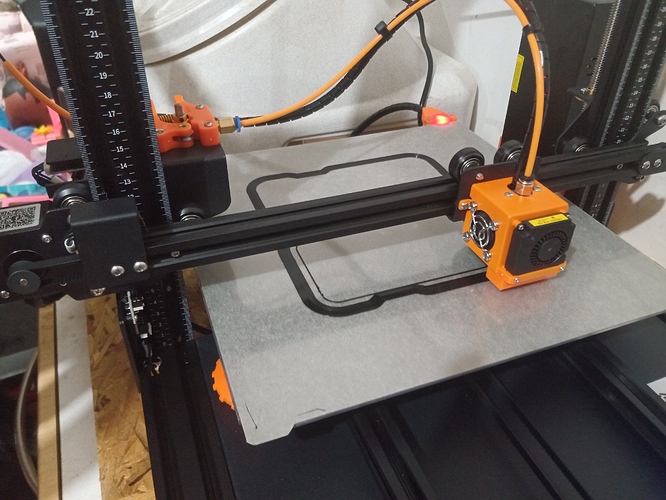

Put the tightly wrapped phone (wrapped in parchment paper) phone face down on a sheet of parchment paper. Start applying the hot glue around the edge of the phone. Remember to leave plenty of access room for each button and hole.

I circled the glue around the camera on the back of the phone and then radiated lines out to each corner and to the center of each side. Then, I put down glue in ever larger circles outward from the camera as center. Each circle was as far from the next circle as the glue was thick.

By the time I put away my tools and threw away the parchment paper, the glue was hard and had cooled down enough to touch.

My pattern looked like a spiderweb (as planned). Remember, I was doing this by hand, using a glue gun that I had to squeeze to push the hot glue out. It looked organic, like roots or worms and the glow-in-the-dark glue was so bright in the dark that I could almost read by it! It was better than I expected but I had to strengthen to parts of it with more glue and cut away parts to give more room to some holes and some buttons.

And, it was protective. I dropped the phone by accident, on concrete, several times. The phone was fine. But, the glue phone case got dirty over time and had to be washed with soap and water every couple weeks.